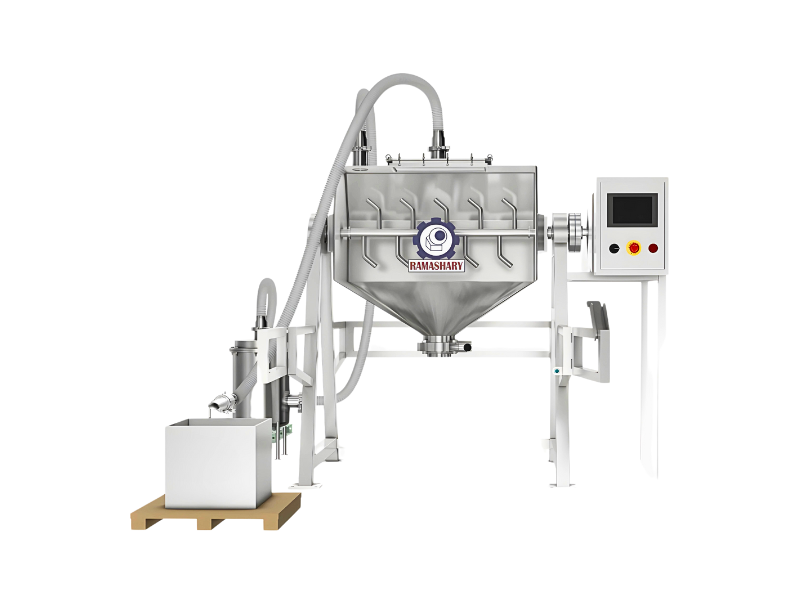

Lipstick Manufacturing Tank

Lipstick Manufacturing Tank

Lipstick Manufacturing Tank

Material Composition

Pigments: at most 15%

Wax: at most 30%

Oil: at Most 70%

Key Features

- The high-speed impeller creates a centrifugal force to properly mix oil, wax, pigments, and other materials of varying viscosities.

- A homogenous end product is obtained through a combination of heat and high-speed rotations.

- The discharge system of the tank helps keep minimal or no trace of the end product in the tank.

- The vacuum system removes oxidation and provides a bubble-free lipstick.

FAQs

Prior to ordering the tank, consider these factors: the number of blades and agitators in the Lipstick Manufacturing Tank, as well as the type and speed of the mixture.

You may properly maintain the Lipstick Manufacturing Tank through regular inspection of the mixing blades and agitators, the temperature control system, seals, and more.

The purpose of adding dyes and pigments to lipstick is to introduce attractive colours to it; this is complemented by appealing shades. Additionally, fragrances are added so that they can cover any unpleasant odours resulting from chemical components used in its production.

The avoidance of contamination with an inner coating, the attainment of uniformity through high-speed rotations and ensuring hygiene in a tightly closed tank.

Heating materials, melting ingredients, mixing components and cooling down before finally filling containers with the finished product are the five stages in lipstick manufacturing.